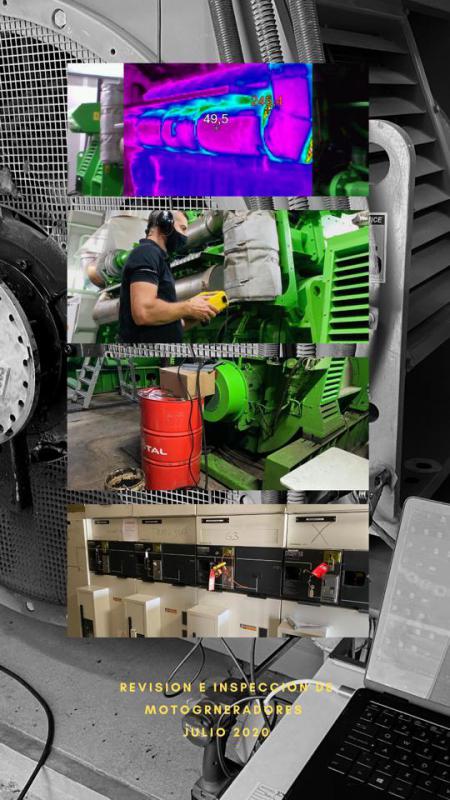

Tests and diagnosis

We carry out predictive and preventive tests, both in the plant and in the workshop, on all types of rotating machinery, with state-of-the-art instrumentation and highly qualified technical staff with extensive experience in the sector.

With the confidence of a highly specialised and professional service, our activity is structured around our experience and dedication that covers a multitude of sectors, including marine and cogeneration.

We are experts in technical assistance

- Visual inspection: core, coils, rotor winding, excitation.

- Evaluation of loose wedges.

- Stator insulation tests: insulation resistance, IP, capacity/delta tg and dielectric losses, partial discharges, ohmic resistance, high frequency shock wave.

- Insulation tests on rotors: detection of short circuits between turns and to ground.

- EDA tests (Insulation evaluation and diagnosis), using the charge and discharge current method.

- Measurement of dielectric strength in DC and AC.

- Capture of thermographic images.

- Measurement and diagnosis of the vibrational state of machinery using spectral analysis, modal analysis and impact test.

- Checking for short circuits between elementary turns using a high frequency shock wave test.

- Vacuum and load test both in the plant and in the workshop.

- Drilling test of straight parts and coil heads.

- Temperature stabilization measurement in rotating machine bearings.

New team

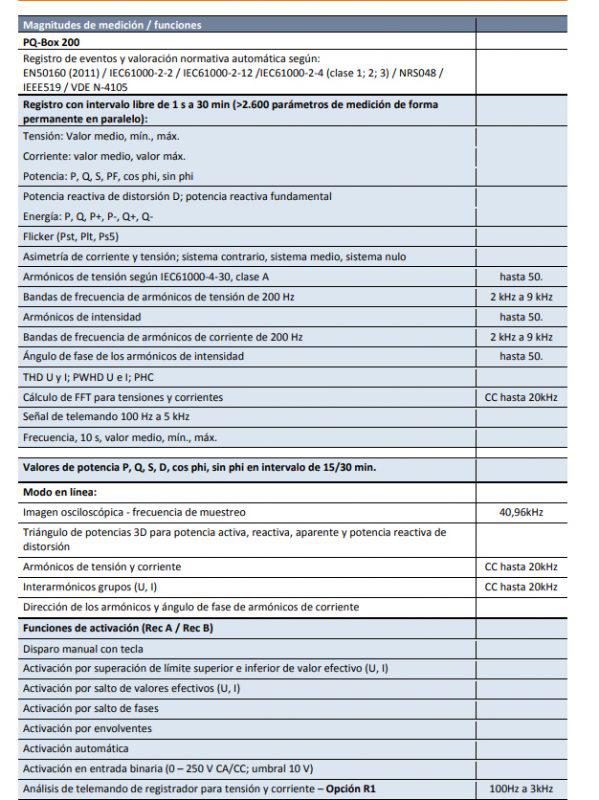

Network analyzer / transient recorder Model PQ-Box 200

- Fault localization

- Power quality assessment according to EN50160 and IEC61000-2-2/-2-4

- FFT analysis up to 20kHz

- Load analysis; energy measurements

- Transient analysis 4 MHz (+/- 5kV)

- Remote control signal analysis

- High-quality software for PQ-Box 100 / 200